¶ Concrete phenomenon

1. The extruder idles and cannot extrude filament normally

2. The filament is loaded normally, but there is a blockage or no material discharge during printing

3. The nozzle cannot extrude the filament, but it can be extruded after removing the nozzle.

4. The filament cannot be loaded normally, and the needle cannot be used to clear it

5. The model appears spongy during printing and is not strong enough

¶ Reasons and Solutions:

¶ 1. The following reasons may exist for the extruder to run idle:

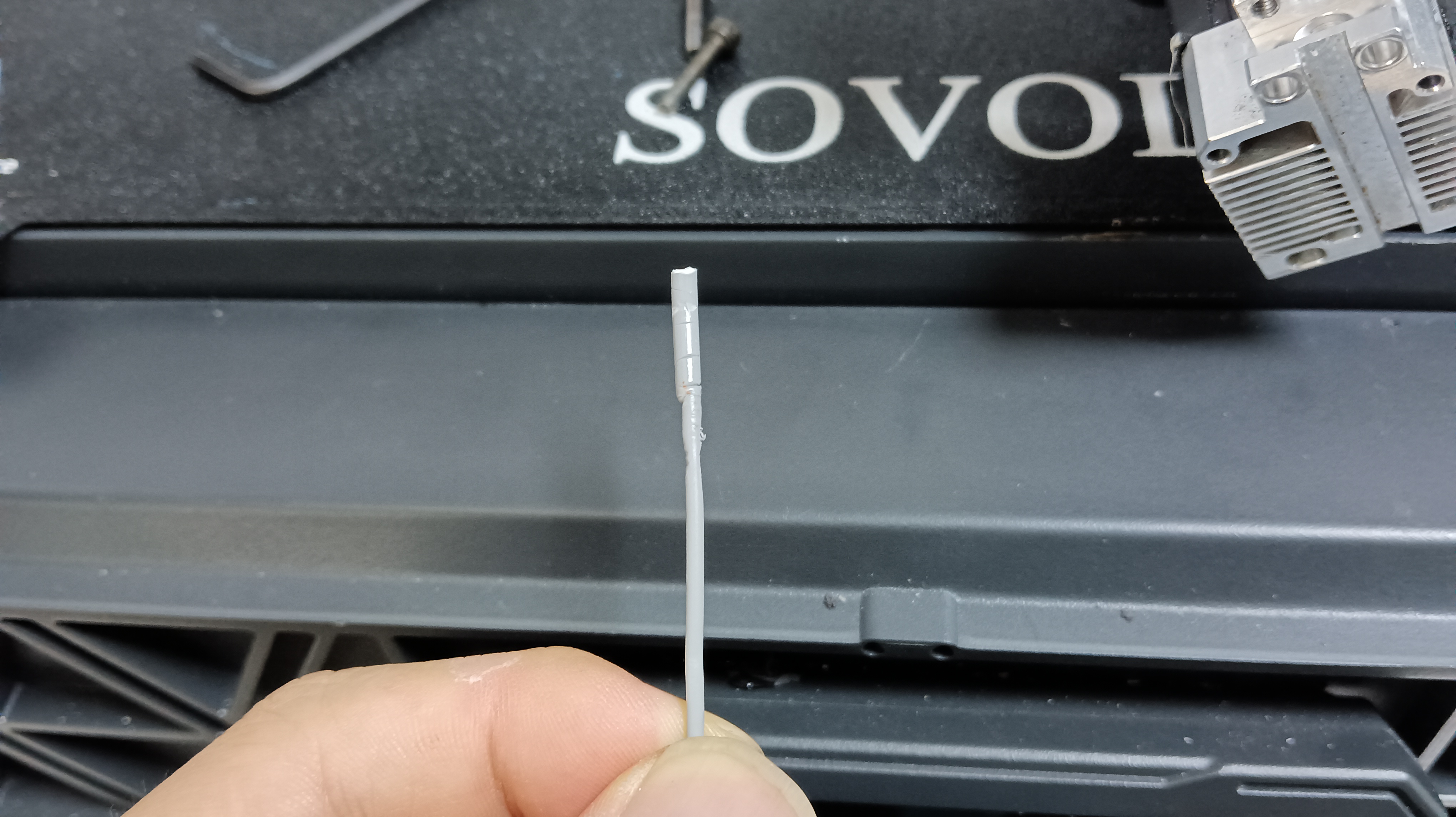

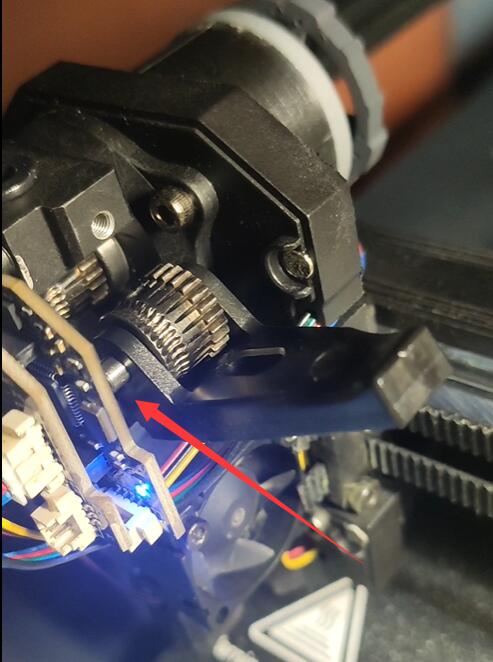

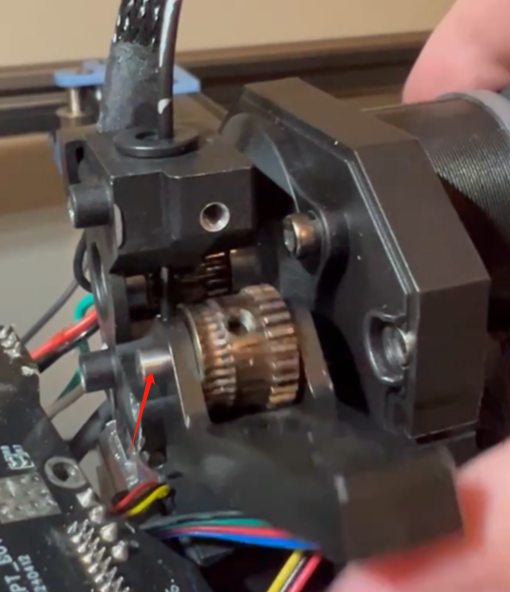

(1) The filament is blocked in the throat or nozzle and cannot be extruded, and the extruder gear causes the filament to wear. You can judge by pulling out the filament and observing the tooth marks on the filament and the melting of the filament end.

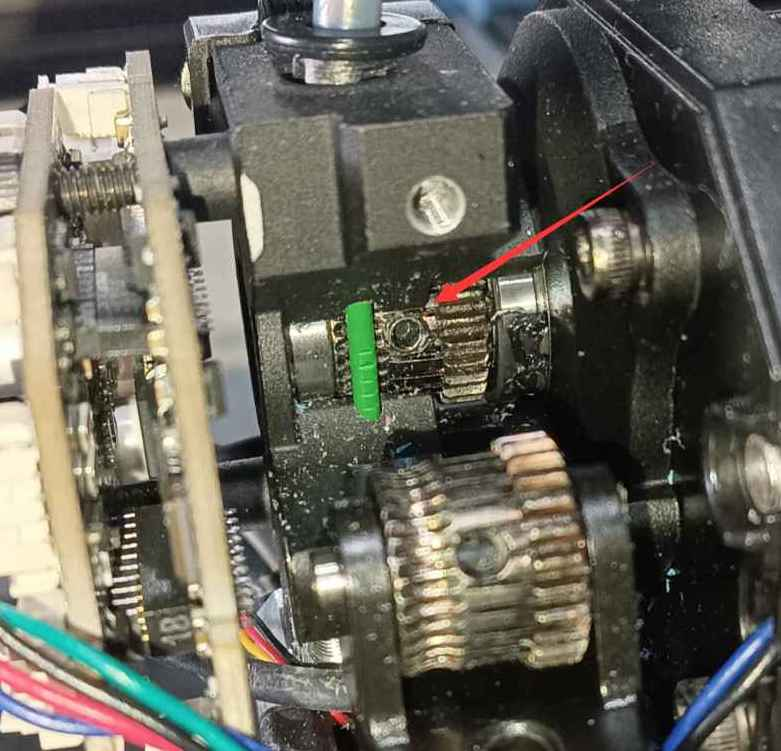

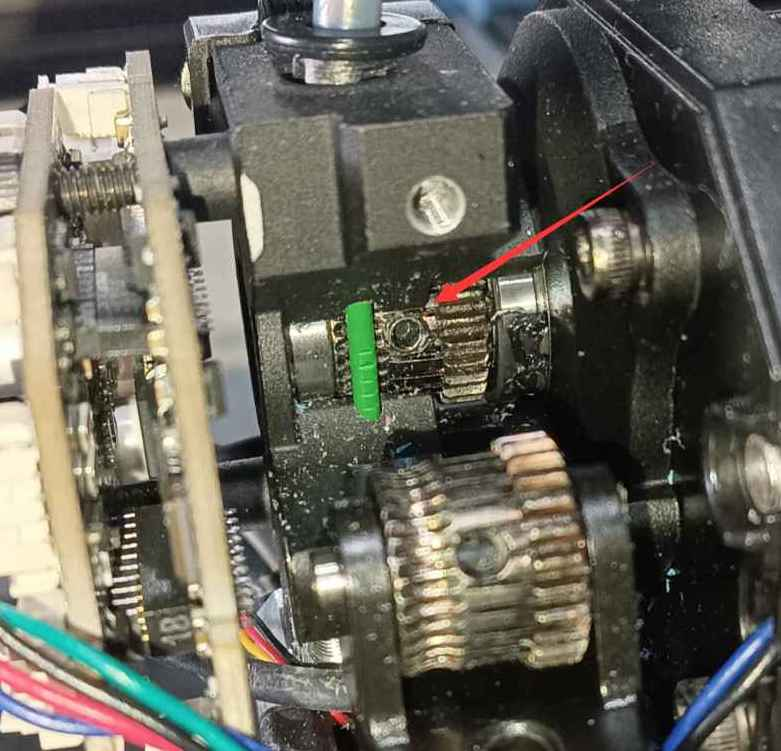

(2) The extruder gear is loose. There are small screws on the extruder gear to fix it. If the screws are loose, the extruder gear and the extrusion motor cannot rotate at the same time, which will cause the filament to fail to extrude normally

(3) The nozzle does not reach the melting temperature of the filament, or the filament becomes brittle and breaks, and the filament diameter is not 1.75mm

¶ 2. Blockage and failure to discharge during printing:

Please refer to the nozzle blockage cleaning video to clean the nozzle blockage;

https://youtu.be/bAOVA6bL-Jw?si=1BFKtEuJOr4XyTbz

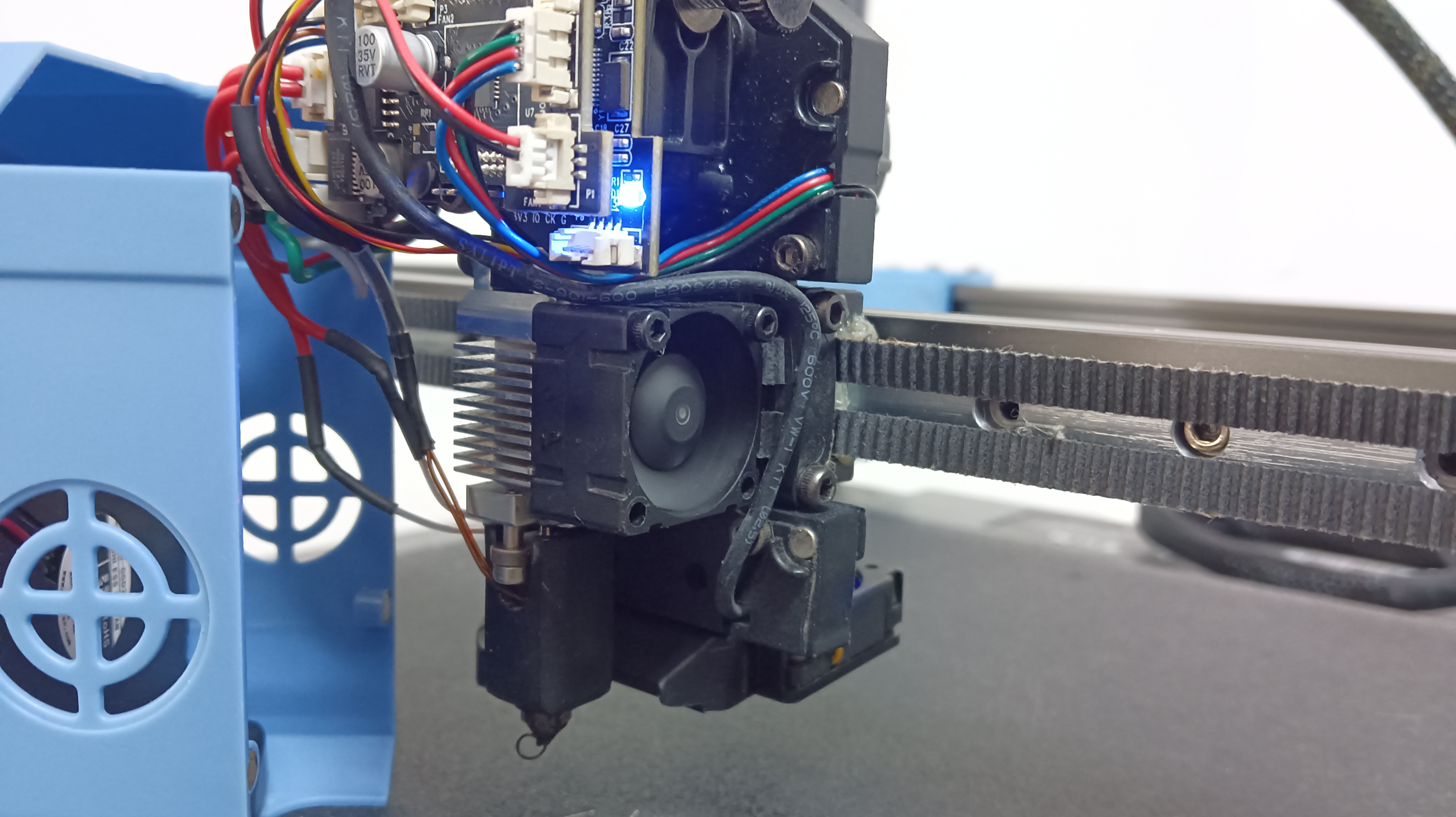

(1) Adjust the hand nut of the extruder to keep the extruder wrench at the appropriate elastic force. Too loose or too tight will affect the normal extrusion of the extruder

(2) Check the printing temperature and printing speed, and select the temperature parameters that match the filament for slicing. Too high a temperature will cause the filament to soften and deform before reaching the nozzle. The filament expands and blocks, causing blockage during printing. After removing the filament, if the end of the filament expands (diameter greater than 1.75mm), it is generally caused by high throat temperature; select the correct printing speed for slicing. The fast printing speed and a low temperature will cause insufficient extrusion flow of the filament;

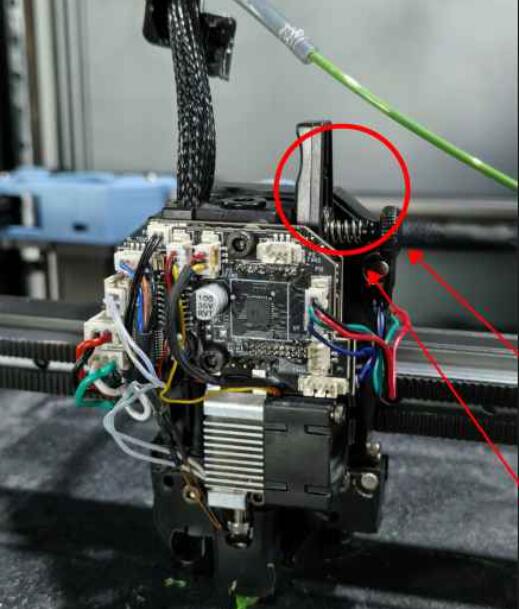

(3) Please check the cooling fan next to the radiator. If the cooling fan stops rotating, the radiator will not be able to cool the throat, causing the throat temperature to be too high and the filament to expand and block;

Solution: Please Heat the nozzle to 60℃ and ensure that the 2515 fan on the heat sink rotates normally. If the error message 8-Mainsail contains "Fan", please jump to the solution for the error message 8-Mainsail contains "Fan"; the cause of the blockage of your machine is that the cooling fan is blocked, which causes the filaments in the throat to expand.

"Error 8—Mainsail Error Message Containing ‘Fan’

(4)Check the metal shaft of the extruder wrench. If the metal shaft moves, it will cause the position of the extruder gear to be misaligned. Please push the metal shaft back to its original position and fix it. If there are residual debris on the extruder gear, please use tweezers and a brush to clean it.

Please refer to Valerie Moore's solution:

https://www.printables.com/model/968689-sv08-extruder-fix

DrewDeeDoo's solution:

https://www.printables.com/model/1020013-sv08-fix/comments

|

|

(5) If your printer has installed a sealing kit, please open the glass panel or use top hat when printing filaments such as PLA, PETG, TPU, etc. to prevent the temperature in the printer chamber from exceeding 35℃.

(6) The nozzle of SV08 is a hardened steel nozzle. Replacing the nozzle with other materials will change the thermal conductivity of the nozzle. Please appropriately reduce the printing speed or increase the printing temperature to prevent blockage during printing.

¶ 3. Filament cannot be loaded, and filament may appear after removing the nozzle:

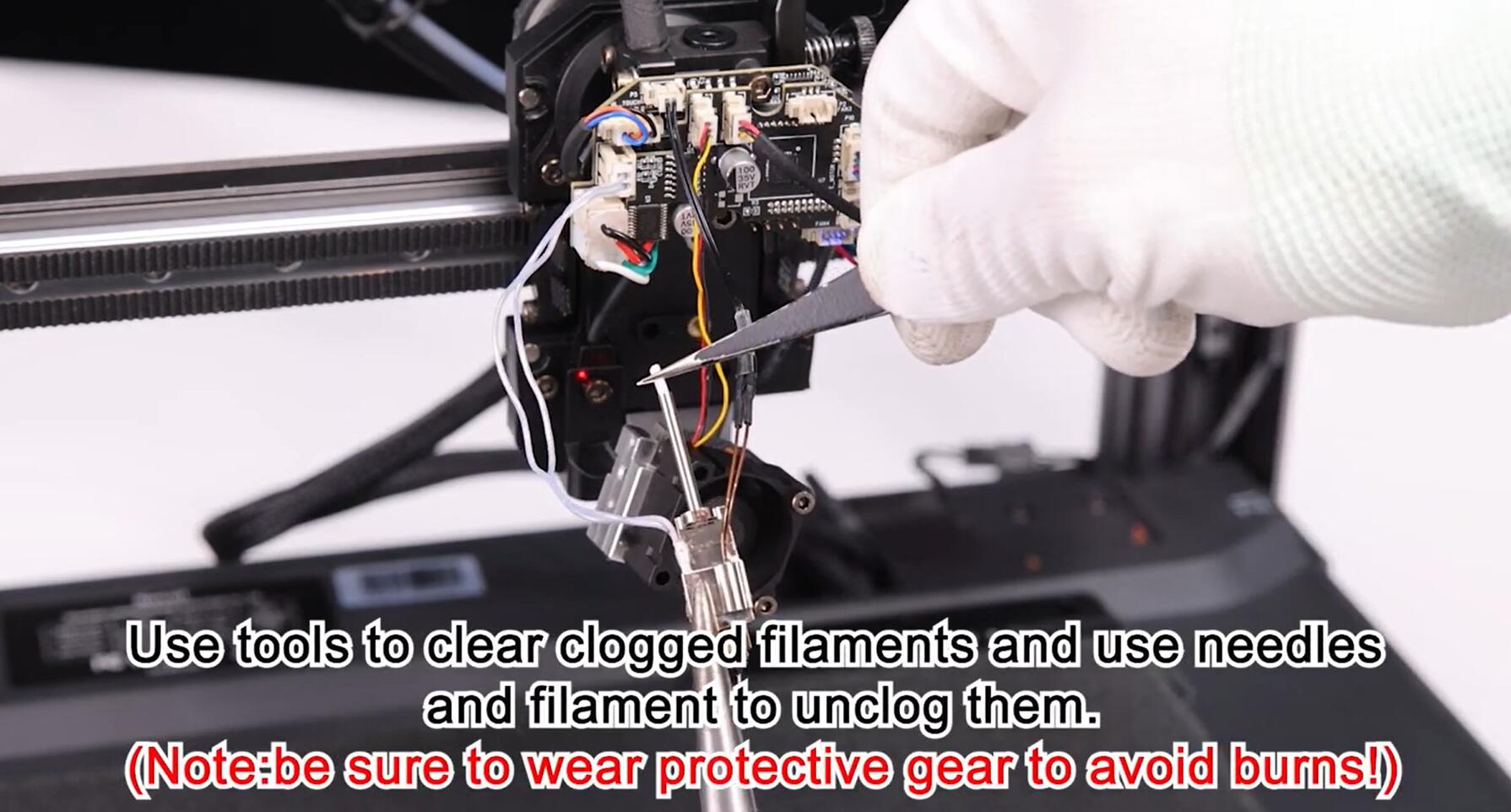

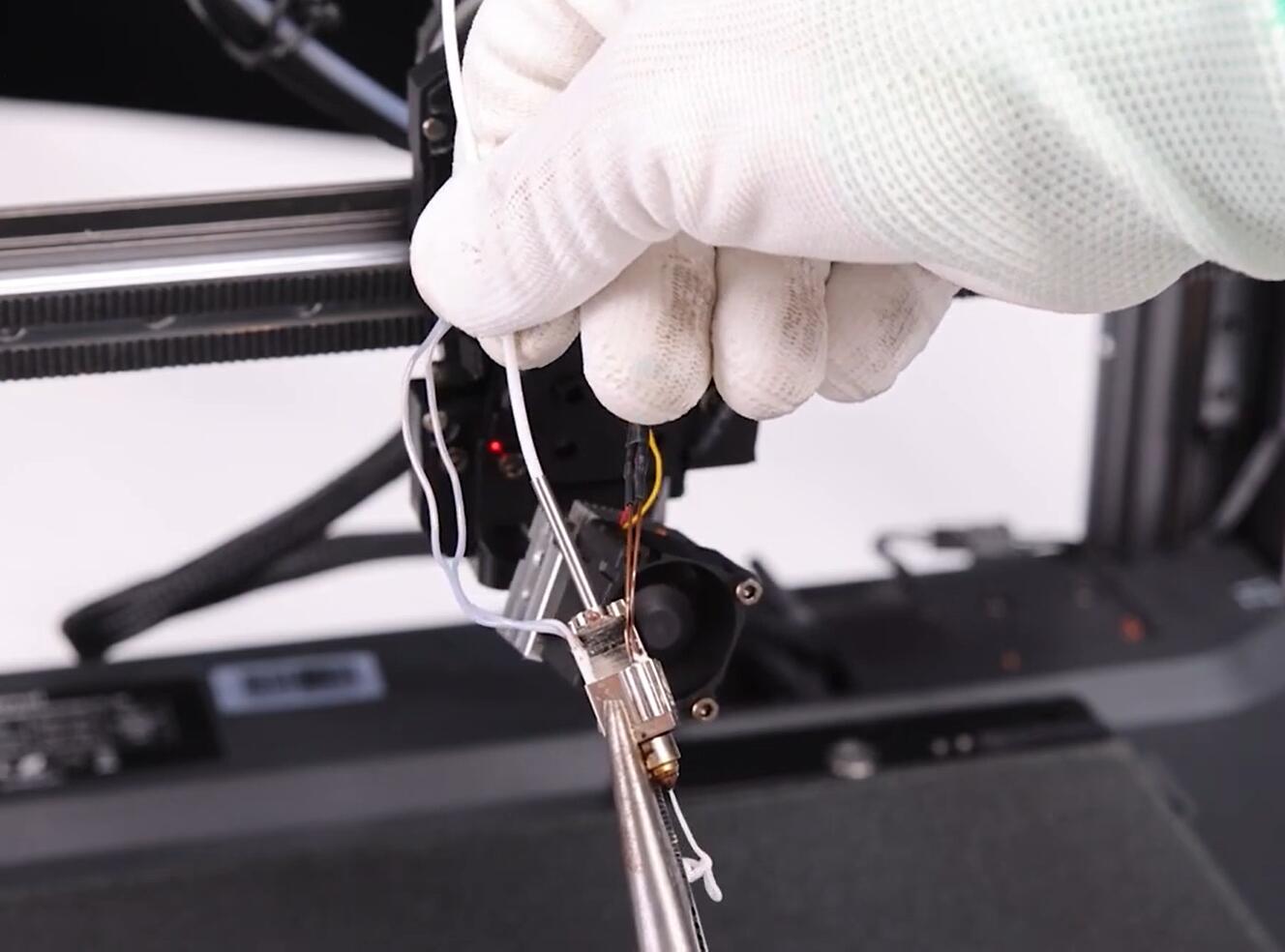

This is usually caused by nozzle blockage. Please use tools to fix the nozzle and heat it separately. Use a needle to unclog the nozzle and then use a new filament to squeeze out the remaining filament in the nozzle. If it cannot be unclogged, it is recommended to replace a new nozzle.

|

|

¶ 4. Filament cannot be loaded normally and cannot be unblocked with a needle:

Solution:

(1) Please determine the location of the blockage first. If it occurs in the extruder, please disassemble the extruder and use tweezers to clamp out the filament. If the filament expands and blocks the extruder, you can use a hair dryer or hot air gun to soften the filament and then clamp it out.

(2) If the filament is blocked in the throat, you can use a hair dryer to blow the throat until the filament softens, then use a tool to remove the filament and use a new filament to clear the throat

(3) If the filament is blocked in the nozzle, please refer to point 3

¶ 5. The model is spongy and not strong enough during printing.

.png)

(1) Please check the extruder part, refer to:

The extruder gear is loose. There are small screws on the extruder gear. If the screw is loose, the extruder gear and the extruder motor cannot rotate at the same time, which will cause the filament to not be extruded normally.

(2) Check the extruder gear. If the extruder gear is worn, please contact Sovol for a replacement.

|

|

.png) |

(3) Please check the slicing parameters of the model, select the appropriate printing temperature and printing speed, and replace other models for printing to eliminate the extrusion shortage caused by the slicing parameters.

(4) Check the nozzle. If the nozzle diameter becomes larger or the nozzle has burrs, please replace the new nozzle. If you replace the nozzle of other materials, please modify the printing parameters.

¶ 6. If you have not solved the problem by following the above methods

please report your operation results to Sovol