Proximity switch troubleshooting solution

¶ Specific manifestations:

If print head strike,proximity switch cannot be triggered normally (the indicator becomes solid or can’t lit), error message appears

¶ Troubleshooting method:

Preliminary investigation:

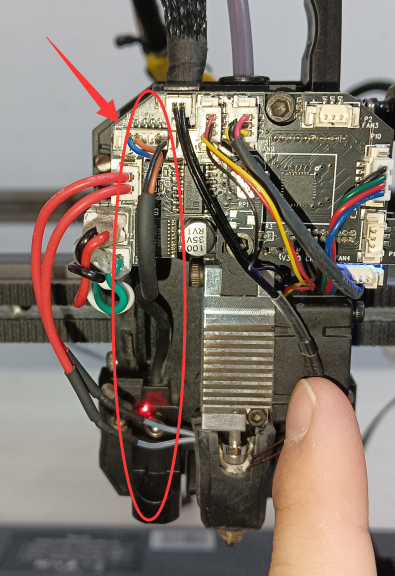

1. Remove the tool head shell, Check the wiring of the proximity switch to confirm that the wiring don’t fall out or damage.

Unplug it and then plug the wiring of the proximity switch again to confirm that the proximity switch circuit is connected correctly.

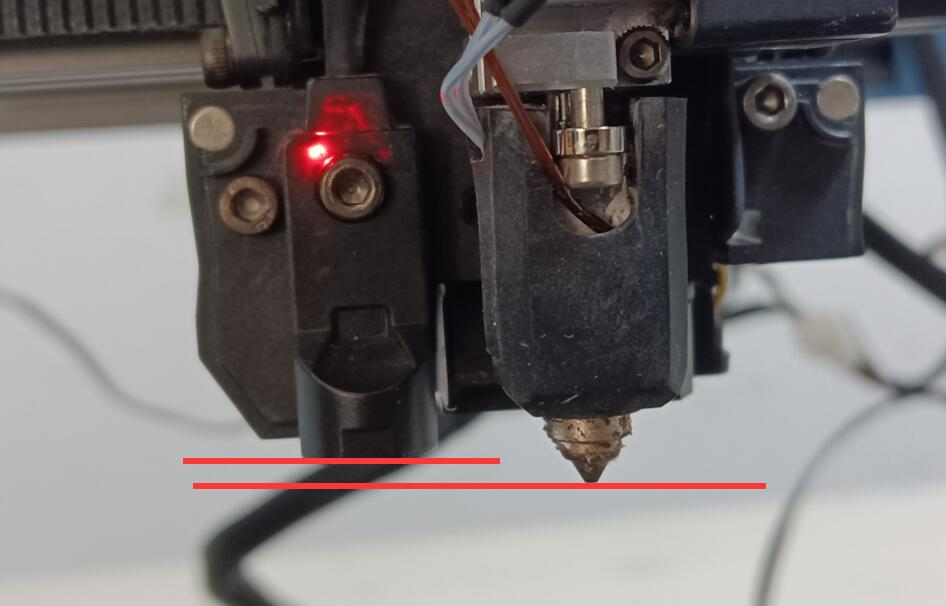

2. Please check the installation position of the proximity switch. The proximity switch is about 2mm higher than the nozzle. Please confirm that the nozzle don’t fall out or loose, and the proximity switch is installed correctly.

3. Turn on the machine, remove the tool head housing, and observe the indicator light of the proximity switch. The proximity switch displays red after turning on the machine in normal working state. After using a metal object (shovel or hexagon wrench) to approach the proximity switch, the proximity switch is triggered and the red light goes off.

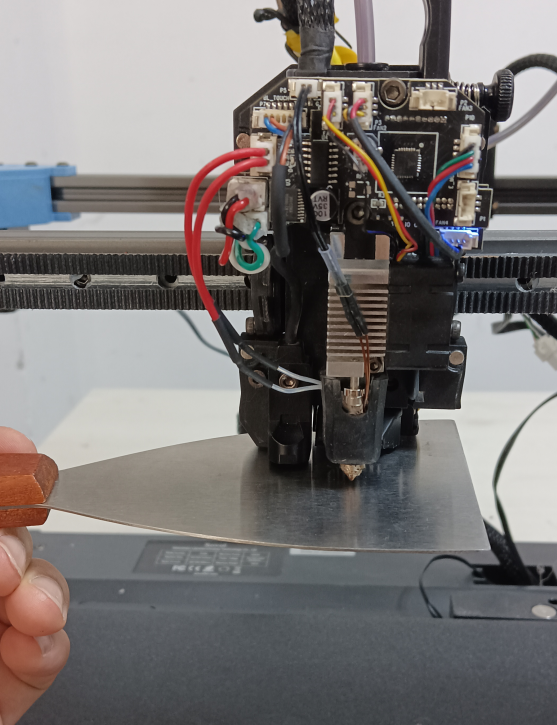

4. Click Auto home, use a metal PEI steel plate or other metal object to approach the proximity switch. If the tool head cannot stop moving in the Z-axis direction, it means that the proximity switch cannot be triggered normally. Please turn off the machine immediately to avoid damaging the printer. Please provide the video to SOVOL, and a new proximity switch will be sent to you for replacement.

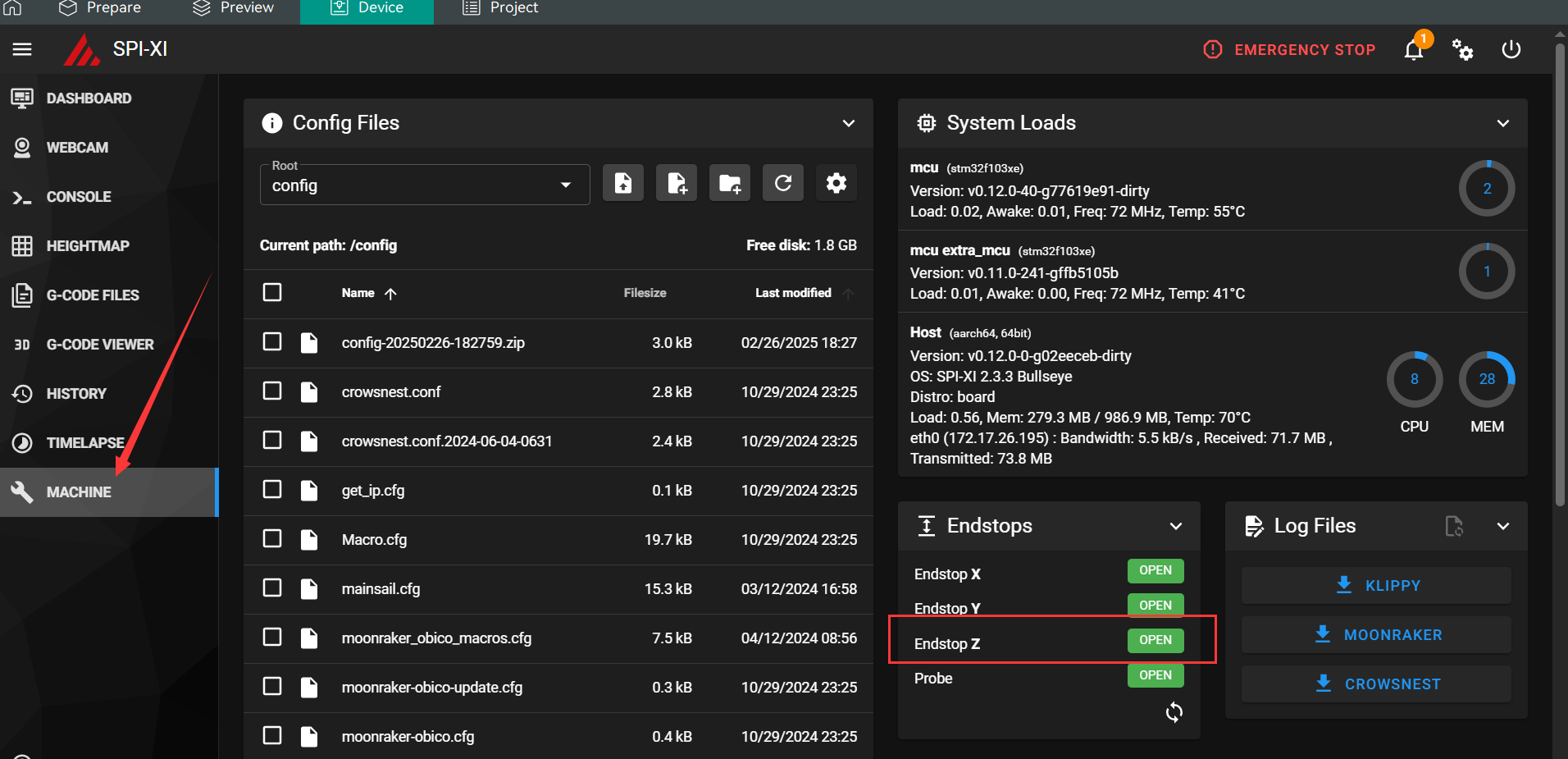

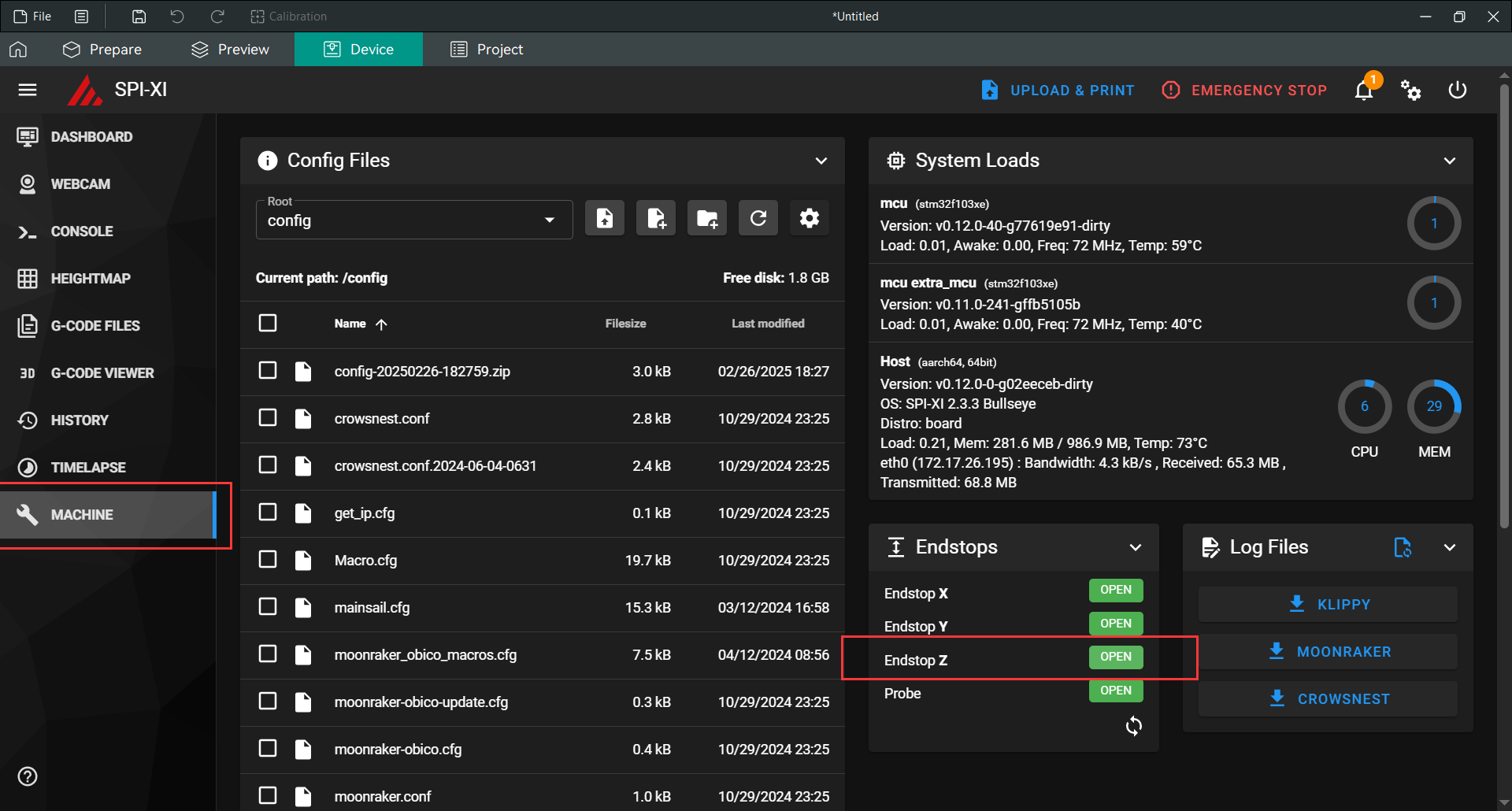

5. Enter the Mainsail interface, click MACHINE, click Refresh Endstops, observe Endstop Z, use a metal object to approach the proximity switch and check the endstop Z status. If it cannot be triggered normally, please feedback to SOVOL.

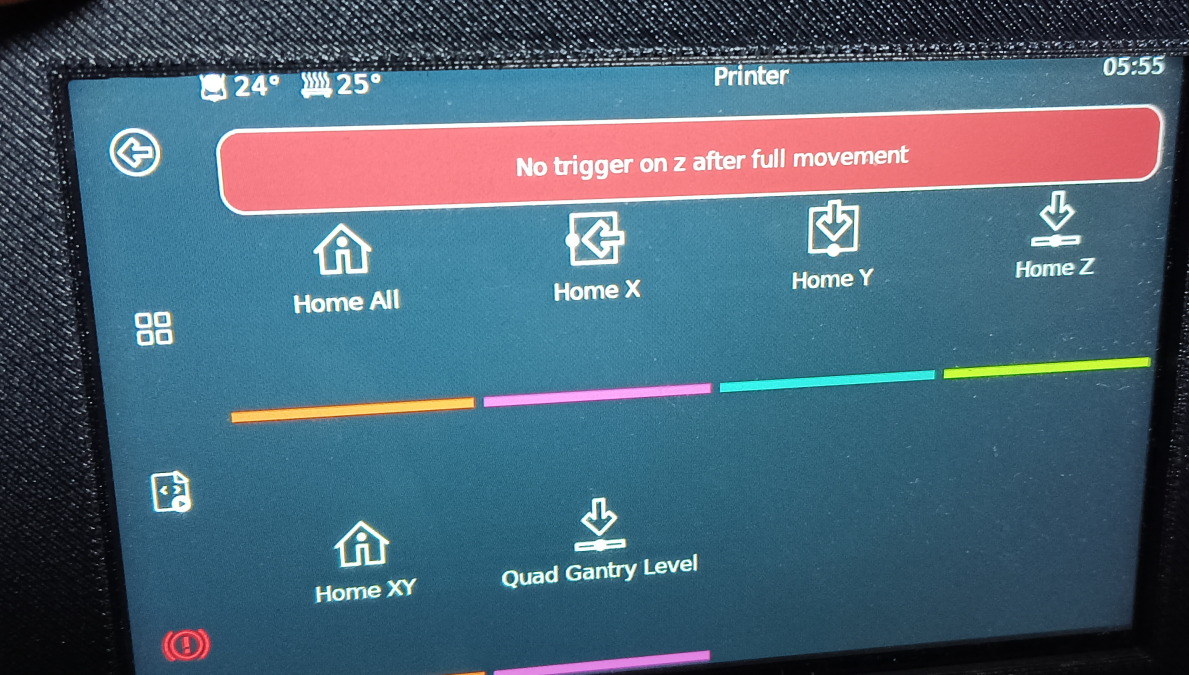

¶ "No trigger on z after full movement"

This error usually occurs when the proximity switch detects a height that is out of range for the second detection.

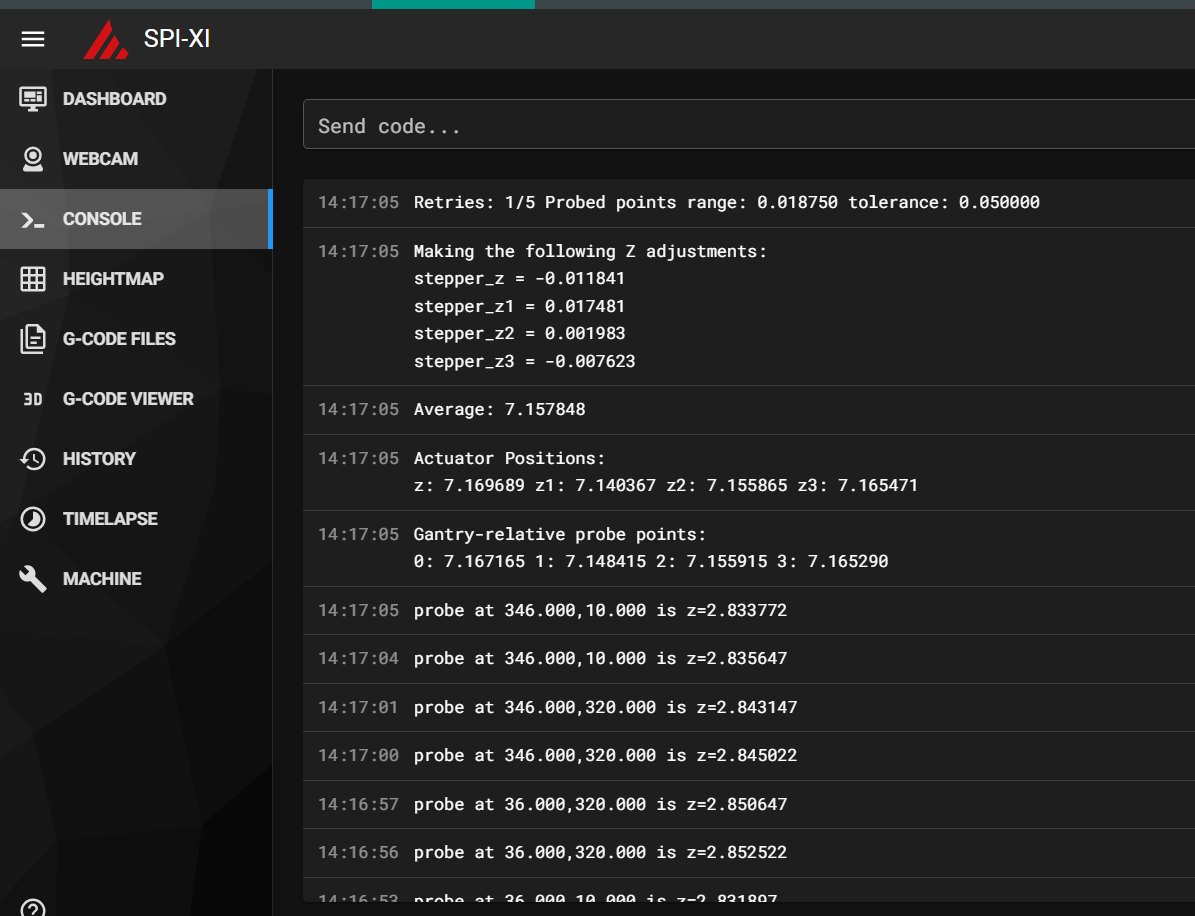

1. Please check the gantry and observe the Z height value of the console when running QGL. If there is a significant error in the height of the gantry, please recalibrate the gantry.

2.If the gantry has been calibrated and the error still occurs repeatedly, please report it to SOVOL for a proximity switch replacement.

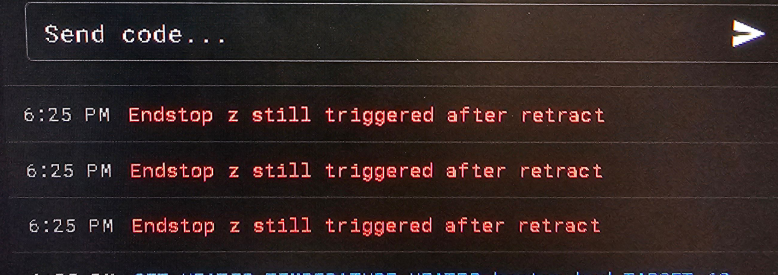

¶ "Endstop z still triggered after retract"

This error usually occurs because the proximity switch has always been in a state of triggering

1. Please check the wiring of the proximity switch to confirm that the wiring is not damaged or short-circuited

2. Use a metal object to approach the proximity switch, observe the changes in the red indicator light of the proximity switch, and observe the triggering of Endstop Z in the Mainsail interface. If it cannot be triggered normally, please feedback to SOVOL to replace the proximity switch.

¶ "communication timeout during homing probe"

Solution:

https://forum.vorondesign.com/threads/error-communication-timeout-during-homing-probe-on-mellow-sb2040.1177/#post-8001

Fix this issue by updating the MCU.py script to increase the probe timeout

Fix this issue by modifying the mcu.py file in the klippy file.

¶ Inaccurate Z offset causes scraping or filament fails to stick to the hot bed

(Please feedback the detailed pictures to SOVOL, because there are many situations where filament fails to stick to the hot bed build plate/nozzle rubs the build plate)

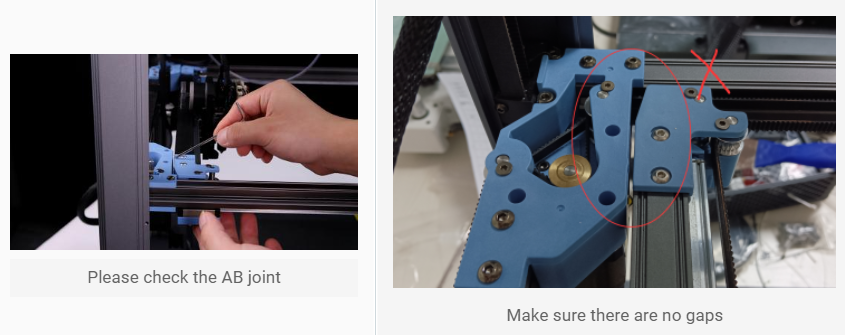

1. Please check the gantry and confirm that the gantry is square. Push both ends of the X-axis at the same time (avoid unilateral push and pull that cause slight deformation of the X-axis position). Push the X-axis to the rear end of the gantry. The X-axis should be close to the AB axis motor mounts. There should be no gap between the X/Y joint and the A/B motors. After squaring the gantry, repeat the QGL steps 1-2 times

2. Please make sure that the Z offset has not been readjusted during the printing process.The adjustment of the Z offset will not be automatically saved when printing. It’s valid for the current printing task.

If the machine is turned off, the Z offset value before adjustment will be restored. Please save the currently adjusted Z offset after completing or canceling the printing. (The knob screen does not show the option to save the adjusted Z offset value. You can save it on the HDMI screen or Mainsail interface)

3. If friction occurs when printing the first layer of the model, please check the nozzle height and confirm that the nozzle is not loose or worn. If the nozzle is loose or worn!

4. If the filament doesn't stick to the hot bed when printing the first layer, or the height deviation of the first layer of the model is large, it is usually caused because the hot bed has not reached a state of thermal equilibrium during leveling calibration. If you use high-temperature filament for printing, it will cause the hot bed to reach a higher temperature in a short time, and the aluminum plate will undergo slight physical deformation. If you need to print high-temperature filament, please heat-soak the hot bed before printing. Please refer to the WIKI tutorial: http://wiki.sovol3d.com/en/How-to-Enhance-SV08-First-Layer-Printing