How to avoid blockage when printing PLA/PETG low-temperature filaments with SOVOL Zero

SOVOL Zero is a fully enclosed 3D printer. The sealed environment is more suitable for printing high-temperature filaments such as ABS, PC etc. It can also reduce the entry of external dust. When a sealed printer prints low-temperature filaments, the temperature of heated chamber rises causing the filament to soften prematurely at the throat or nozzle, resulting in thermal creep and increasing the probability of plugging.

PLA and PETG are low-temperature materials. The melting point range of PLA is 190-220℃, while PETG is 220-250℃. Common causes of blockage include improper temperature setting,filament dampness,extruder problems, and unreasonable retraction settings. In a sealed environment, temperature control is more critical because the internal temperature may be higher, and it is necessary to ensure that the heat dissipation of the throat is sufficient to prevent heat creep.

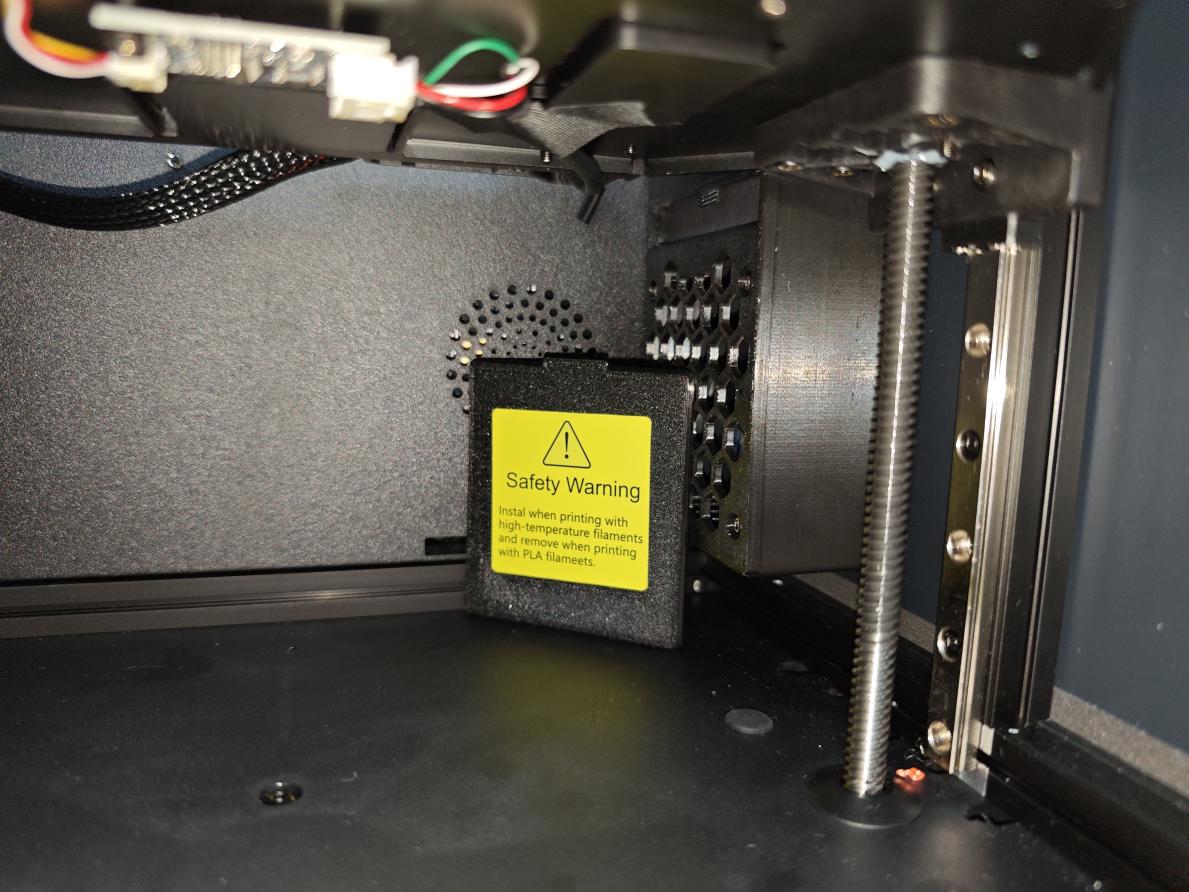

The function of the exhaust fan is usually to filter harmful gases and dissipate heat of chamber temperature. When printing high-temperature filaments, the chamber temperature must be kept stable and the exhaust fan cover must be closed. If printing low-temperature filaments such as PLA/PETG, the cover must be removed to keep the air in the chamber flowing and prevent the hot end from overheating.

Regularly check the status of the nozzle and Teflon tube to prevent filament residue from causing blockage. If the print quality of the model deteriorates, please check the extruder gear to avoid blockage caused by insufficient or excessive extrusion.

¶ Temperature control:

1. Temperature control and hot end fan heat dissipation

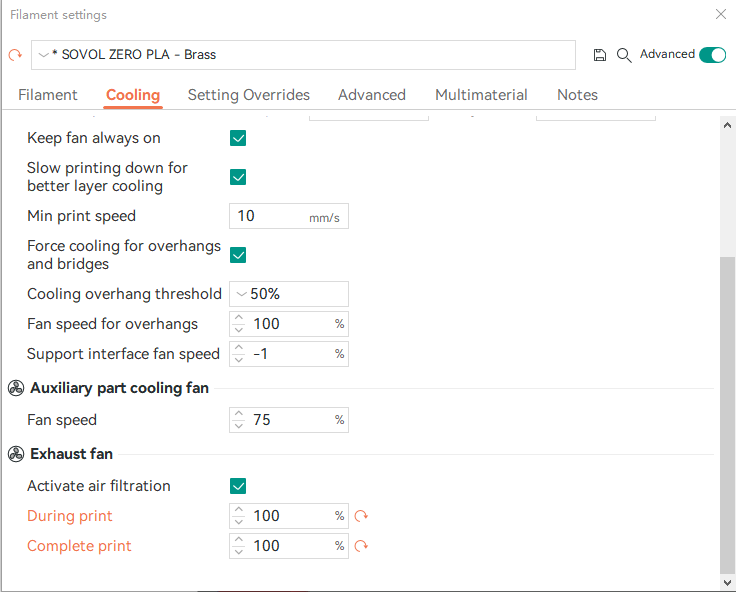

(1) The throat cooling fan must be always on to ensure that the throat cooling fan maintains 100% speed throughout the printing process to prevent heat creep.

(2) Heat creep is the most common cause of blockage in a sealed environment. Heat will be transferred from the heating block to the throat, causing the filament to soften prematurely and cause blockage.

(3) Check the hot end cooling fan: the fan should be aligned with the heat sink to confirm that the fan is working properly.

2. Choose the appropriate printing temperature

(1) PLA: 190-210℃ (recommend starting temperature 200℃, gradually adjust)

PETG: 220-240℃ (recommend starting temperature 230℃, avoid exceeding 250℃)

Temperature that is too high will cause the filament to soften prematurely, resulting in nozzle clogging.

Temperature that is too low will cause the filament to have poor fluidity after melting, causing the extruder gear to slip.

(2) Try to use different brands of filaments for testing. If you have requirements for printing quality, please give priority to high-quality high-speed printing filaments.

3. Check the slicing parameter settings

(1) Turn off the exhaust fan when printing the first two layers to ensure stable adhesion of the first layer.

(2) Turn on the exhaust fan in the slicing software and remove the fan cover in the printer. Keep cold air circulating in the printer cavity.

(3) Choose the appropriate cooling threshold value to improve printing results

¶ Filament selection and pretreatment:

1. Use a sealed box to store the filament.unboxing filament with prolonged air exposure will absorb moisture in the air and affect the printing quality.

2. If you have a filament drying box, please dry the filament before printing. The drying time can refer to the recommended time of the filament drying box.

3. Choose a filament with a diameter of 1.75mm to avoid large fluctuations in diameter that cause changes in extrusion pressure. It is recommended to use high-speed printing filament.

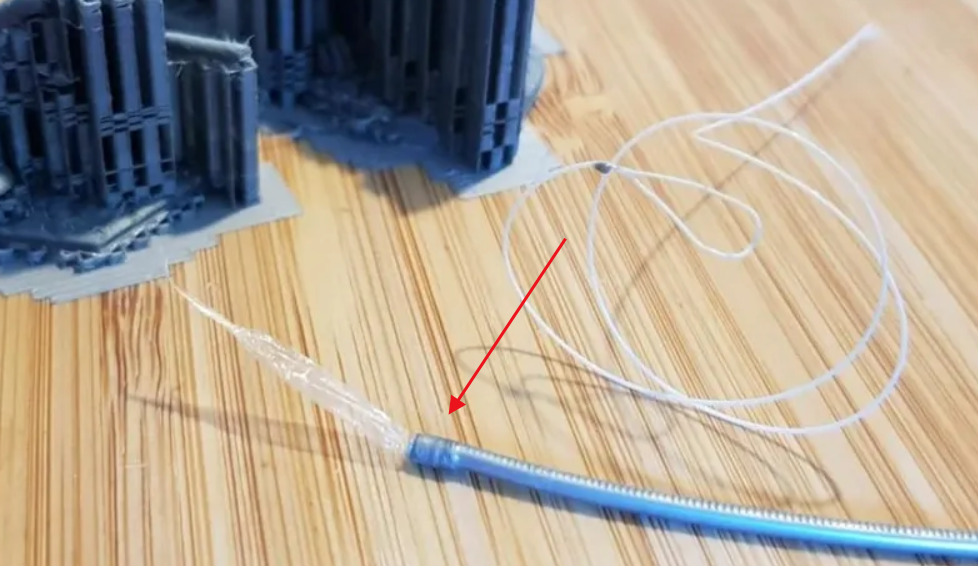

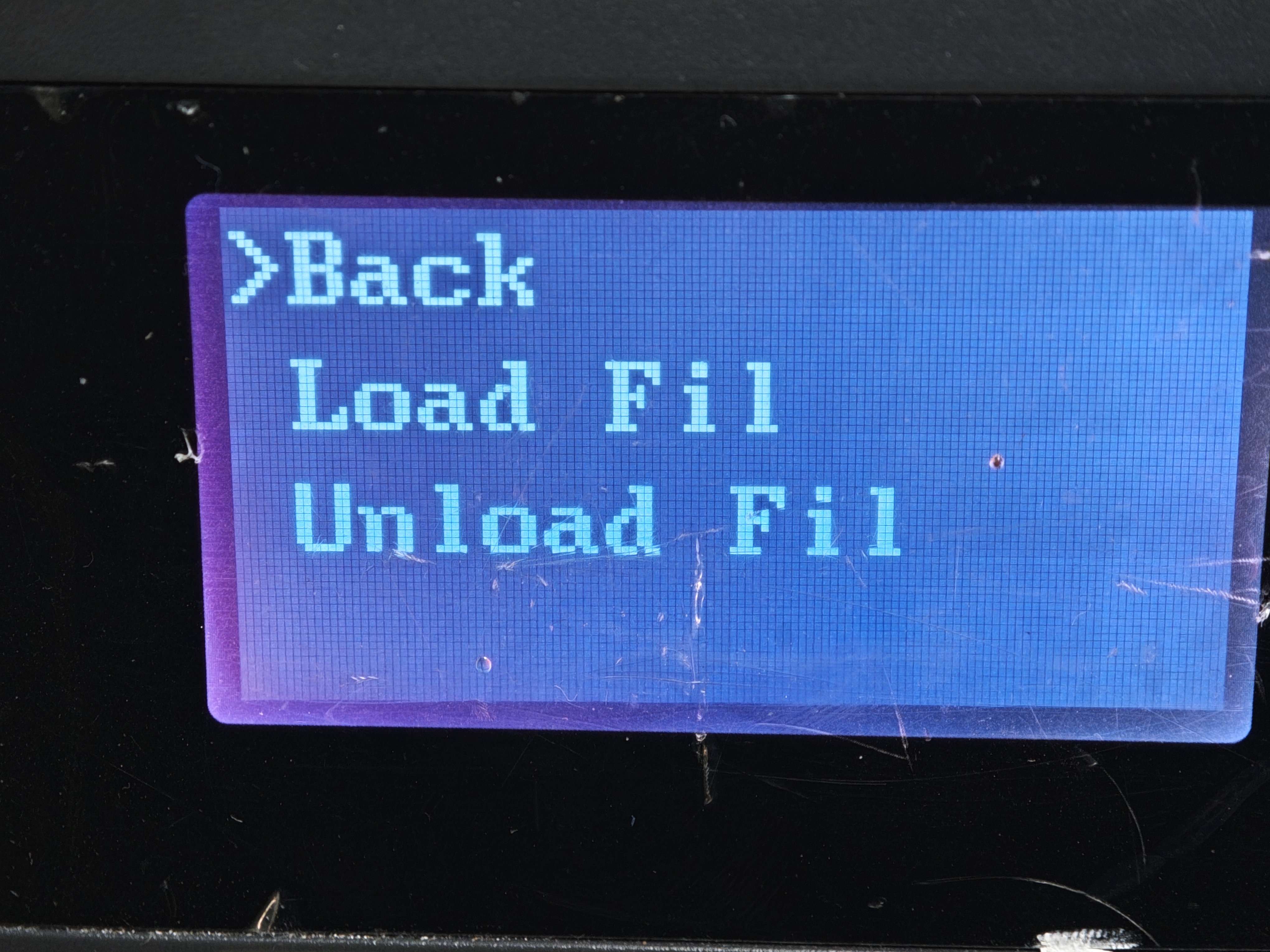

3. Install and unload filaments

Please use automatic filament loading and unloading. Direct insertion or removal of filaments can easily cause filaments to be blocked in the nozzle or throat.

Note: Execute after each roll of filament is used or when switching materials.

The above measures can significantly reduce the risk of blockage in PLA/PETG printing in a sealed environment, while balancing the heat dissipation and exhaust requirements to ensure stable and efficient printing quality.